PLASTIC AND INJECTION-MOULDED PARTS

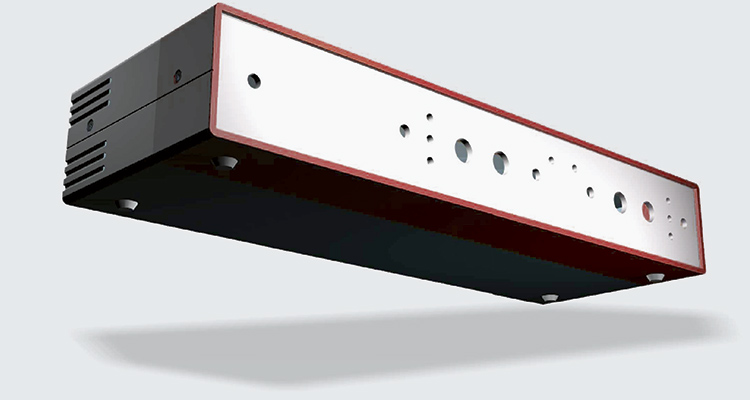

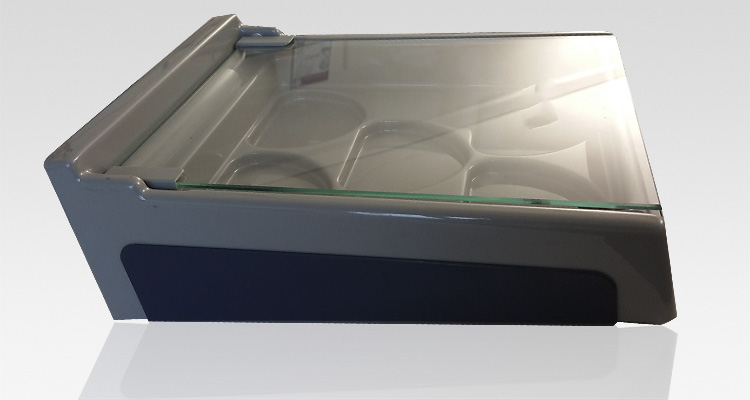

Plastic housings – customised solutions without tooling costs

| Application areas: | enclosures, suitcases, covers etc. |

| Surface: | matt, gloss or metallic effect |

| Material: | Ultem, PEEK, PPS, Nylon, Delrin, PTFE, Torlon, CTFE, HDPE, ABS |

| Lettering/Printing: | screen printing |

Plastic housings – customised solutions without tooling costs

| Application areas: | enclosures, suitcases, covers etc. |

| Surface: | matt, gloss or metallic effect |

| Material: | Ultem, PEEK, PPS, Nylon, Delrin, PTFE, Torlon, CTFE, HDPE, ABS |

| Lettering/Printing: | screen printing |

Fulfilled requirements

- Ideal for batch sizes between 1 to 1000 pieces

- Competent development work all around your case

- We visualise and simulate your enclosure solution in 3D

- Without tooling costs

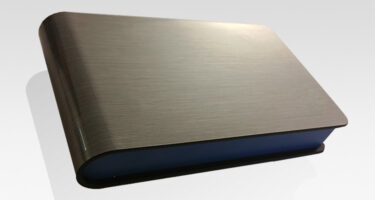

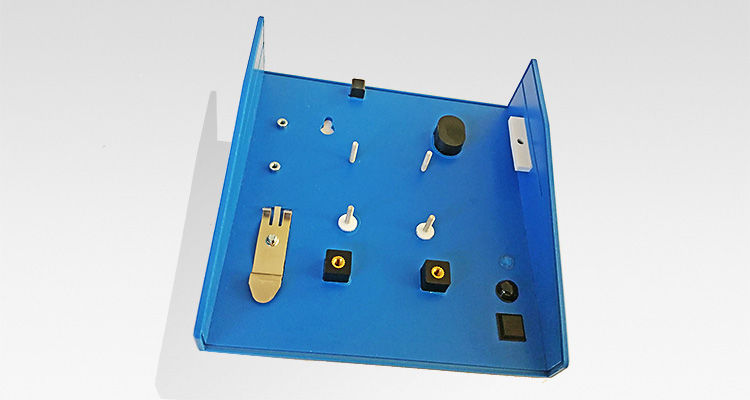

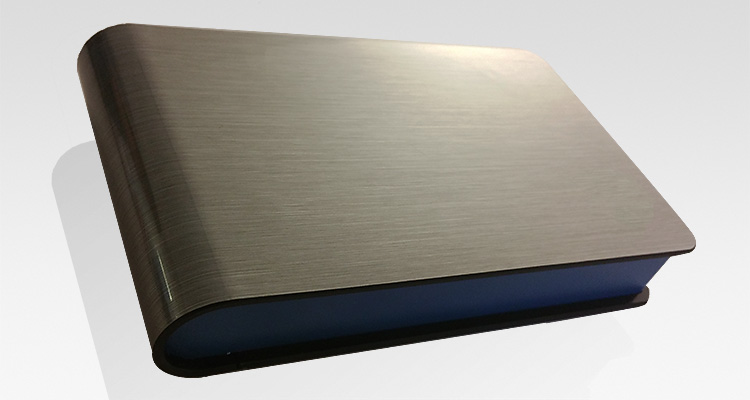

Unique plastic housings

| Application areas: | switching and input systems, power supplies, mobile devices, industry, medical technology |

| Surface: | matt, gloss or metallic effect |

| Material: | Ultem, PEEK, PPS, Nylon, Delrin, PTFE, Torlon, CTFE, HDPE, ABS |

| Lettering/Printing: | screen printing |

Unique plastic housings

| Application areas: | switching and input systems, power supplies, mobile devices, industry, medical technology |

| Surface: | matt, gloss or metallic effect |

| Material: | Ultem, PEEK, PPS, Nylon, Delrin, PTFE, Torlon, CTFE, HDPE, ABS |

| Lettering/Printing: | screen printing |

Fulfilled requirements

- Ideal for batch sizes between 1 to 1000 pieces

- Competent development work all around your case

- We visualise and simulate your enclosure solution in 3D

- Without tooling costs