Modern input systems – an overview

Operating devices is the norm for us. The cell phone alone accompanies us day and night. It reacts to information that we enter in one way or another. The technology for touch operation in smartphones is called PCAP or Projected Capacitive Touch. All devices with which we communicate require modern input systems. On a notebook, we normally use a keyboard and a mouse. Ticket machines, for example, use buttons, often in conjunction with a screen. Dishwashers, ovens, mixers – all these appliances have buttons. In cars, we also use buttons, touch screens, rotary wheels, joysticks, voice commands and sometimes gestures – an expressive movement with which we transmit a command. Depending on the input and requirements, different technologies are selected as the HMI (Human Machine Interface) or input system.

Different Types of

Pressure Sensors for

Input Systems

Behind each button is a type of a sensor. It detects if a key is pressed. This activates a consumer load or transmits the information of the keystroke to a control device. The typical, simple switch, such as a light switch, closes or interrupts the circuit. Light on: circuit closed; Light off: Circuit interrupted. In this case, the consumer is the light bulb, today an LED light. The circuit is closed or interrupted by a mechanical movement. Most of the buttons are based on the principle: ON – OFF.

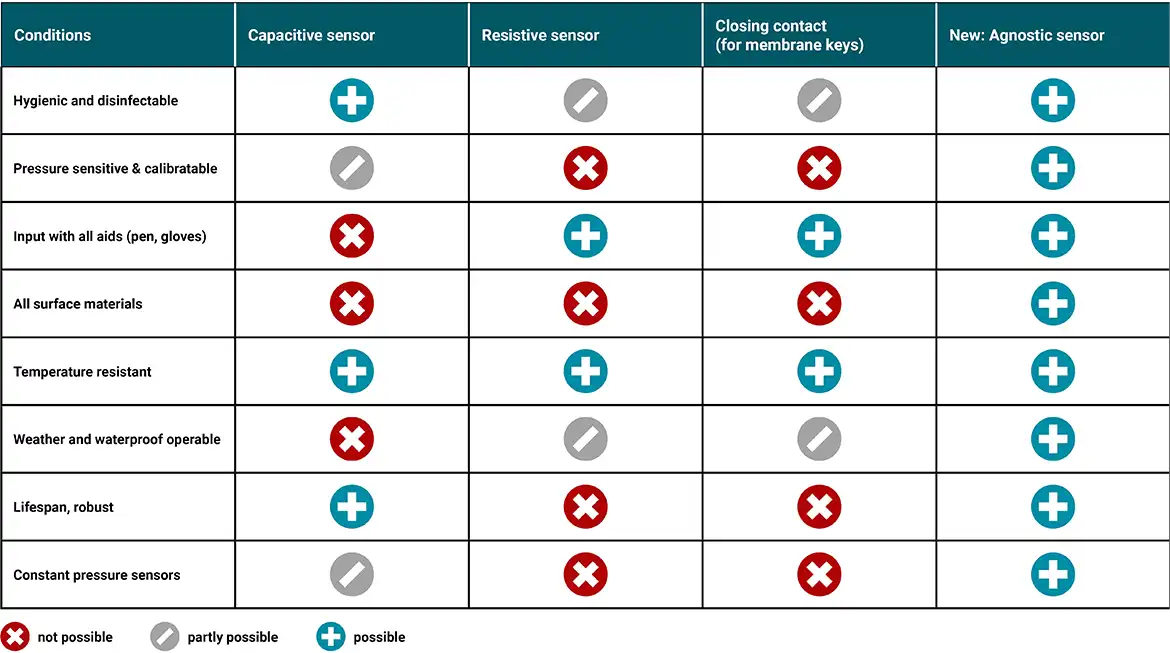

Typically, input systems are implemented as follows:

- Closing contacts

- Resistive Sensors

- Piezoelectric Sensors

- Capacitive Sensors

- Agnostic Sensors

Comparison of the most common input systems

Computer keyboards, copier keys, buttons on various household appliances, etc. usually have short-stroke switches or microswitches. With closed membrane switches, contacts are sometimes closed by a metal dome that is pressed through. Most push-buttons have such “closing contacts”. The advantages: simple signal evaluation, natural tactile feedback through key stroke, no power consumption in idle state. The disadvantages, however, are: Mechanical opening for button, existing dirt edges, not waterproof, limited service life or in case of membrane keypads: plastic foil as operating front – the design options are limited. Both variants are susceptible to vandalism.

How a resistive touchscreen works

The resistive touch, such as a resistive touch screen, works as follows: the front foil is pressed onto the back foil and closes a contact. In this case, the electrical conductors are almost invisible, so that the screen remains visible behind the resistive touch. Such a keypad consists of traces that are often executed as a matrix. The movable foils as a surface are a prerequisite and restrict design variants. If the front foil is defective, the input system usually stops working. The resistive touchscreen has now been largely replaced by capacitive touch or PCAP.

When a capacitive sensor makes sense

A capacitive sensor works completely differently: it is a type of sensor that uses the changes in the capacitance of an electrical capacitor to detect information about the environment or react to touch. The capacitive sensor contains electronics that detect the change in capacitance and convert it into an electrical signal.

In order for a change in capacitance to be detected by approaching or touching a finger, it is a prerequisite that the input front is non-conductive. Glass or plastic as input front meets this requirement. However, all metallic surfaces are unsuitable. If the key-triggering finger is electrically isolated, for example by wearing gloves, no change in capacitance can be detected – no signal is triggered. This also applies when operating the device with a pen or key. If the capacitive user interface is wet or dirty, the resulting change in capacitance is filtered out by complex algorithms. The difficulty is to distinguish an intentional keystroke from other disturbances. We realize this when the intended function does not occur or is triggered with a delay (e.g. in the case of ceramic stoves). Depending on the humidity, the use of hand cream, the degree of soiling, etc., the capacitive technology is vulnerable, the button press is not recognized or only recognized after repeated use.

Basically, a capacitive sensor can also be used as a pressure sensor. The control surface is shifted or deformed at the touch of a button, which changes the plate spacing and thus the electrically measurable capacitance. This also works with metallic fronts. However, reliable signal evaluation is not easy to achieve, as the capacitance is also influenced by heat.

A piezoelectric pressure sensor

works via electronic

evaluation

The piezoelectric pressure sensor also falls under the list of common input systems: a metallic membrane is coated with piezoelectric material and firmly connected to an operating front. When the button is pressed, the piezo disc is slightly stretched and thus emits a voltage that can be evaluated electrically. The electronic evaluation of voltage is more complex than, for example, a change in resistance. It can be difficult to distinguish between a “heat signal” with rapid temperature changes and a button press. The technology is less suitable for long keystrokes.

What is meant by

strain gauges?

A common and familiar pressure sensor is based on strain gauges. Most weight measurements for scales are based on this. Strain gauges detect changes in electrical resistance caused by the strain or deformation of a material.

Agnostic Touch Technology

as a new solution among

input systems

The Agnostic Touch Technology uses strain gauge technology. The small, highly sensitive force sensor with integrated Wheatstone bridge circuit is soldered onto a printed circuit board using automated SMT assembly. This, in turn, is glued to the back of the operating front. The mechanical bending caused by the push of a button is transmitted through the sensor with a change in electrical resistance. Usually, there is one sensor per button. Depending on the geometry or application of the input, different arrangements make sense. This is because the higher the force, the greater the mechanical deformation of the user surface. The electrical resistance changes linearly with the bending. As a result, the force of the keystroke serves as an additional input dimension.

What makes the Agnostic Sensor so

special?

There are no limits to the material of the operating surface. Only a minimal mechanical bend in the micrometer range is required on the operating surface. With a 1 mm thick stainless steel front, a force of a few 100 grams is sufficient – similar to a touch on a smartphone. This is almost unimaginable and very impressive.

In addition to metallic surfaces such as stainless steel or aluminum, glass, ceramic or a wooden front panel are also suitable. An imperceptible mechanical bend is sufficient. It can typically be made by a finger, but also by a pen, key or tool, regardless of whether it is wet, cold or dirty.

With Agnostic Touch Technology, the signals from all sensors on the input front are evaluated by software. Any force applied anywhere on the surface is reliably registered. This results in stable and clearly assigned key signals. For example, pressure between two buttons is identified but not interpreted as a signal. The same applies to undefined bending. By calibrating the input system with a defined force, different buttons can be assigned unique signal patterns. No matter what material the input front is made of, the button sensitivity is the same and can be changed as required.